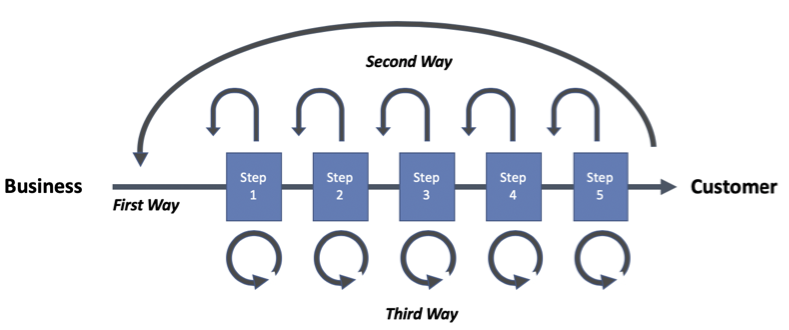

We want our engineers to be as productive as possible. The ‘three ways’, a term coined by Gene Kim, describe a philosophy to guide the work that engineers do, based on lean manufacturing principles.

First Way: Work always flows in one direction – downstream, towards delivering business value. One way to speed up the flow is to reduce the amount of Work in Progress (WIP) by having smaller pieces of work in the left-to-right pipeline. Your flow will never be faster than your biggest constraint in that flow's path. WIP only creates value as a finished product at the end of the flow, so removal of constraints and smaller pieces of work help deliver value faster, and which also enable faster feedback …

Second Way: Create, shorten and amplify feedback loops, from right to left. Here, the focus is on increasing both the number of feedback loops from all points in your flow and also on how fast you are getting that feedback. The more feedback loops there are, the more quickly the concerns are raised and solved. Automation of the work and QA is a key method of adding feedback loops.

Third Way: Continued experimentation, in order to learn from mistakes, and achieve mastery. Continuous experimentation is not an easy mindset to cultivate since it requires taking risks and learning from both successes and failures. We need to continually put tension into the system, so that we're always reinforcing habits and improving something.

In another post we talk about the term 'digital' refering to the company moving with speed and agility rather than a reference to technology, and that speed and agility may be better defined as velocity, which gives momentum, focus which ensures direction and governance, and flexibility which provides the enabling environment for success.

We can improve velocity by having small teams complete small items of work - its not complete until its finished, and smaller items of work are finished more quickly and are less likely to suffer impediments to progress. By empowering the teams to create what is required to add value for the customer, and by encouraging experimentation and iteration with fast feedback, the sooner the end-game is reached.

People can be scared of feedback, but done well, and constantly, it soon becomes the new normal.

Next: Corporate Memory

There is certain key information that the company just has to know. If it's not stored anywhere central then it can't be found. We explore this vital capability in Corporate Memory.